Sonipat, Haryana

- GST NO. : 06AGCPC6470E1ZT

1 Piece (MOQ)

| Business Type | Manufacturer, Supplier |

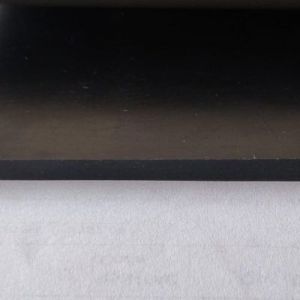

| Material | Rubber |

| Shape | Rectangular |

| Color | Black |

| Click to view more | |

Preferred Buyer From

| Location | Anywhere in India |

Product Details

DIAMOND PULLEY LAGGING

TROUGHED PULLEY CONVEYORS

PULLEY LAGGING

INTRODUCTION

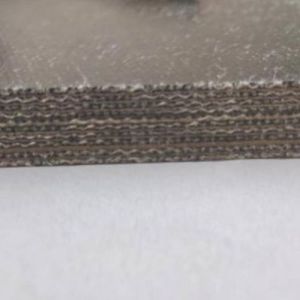

Lagging is the term used to describe the application of a coating, cover or wearing surface which is sometimes applied to pulley shells.

Lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the pulley. Notably drive pulleys are often rubber lagged for exactly this reason.

This section provides some useful information regarding the different types of lagging as well as some technical details and recommendations for lagging of pulleys.

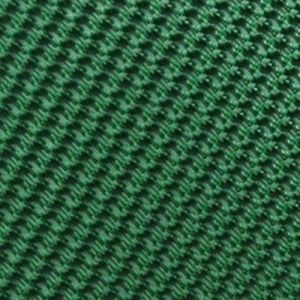

DIAMOND PULLEY LEGGING

Rubber lagging is applied to pulley shells in order to improve the friction between the pulley and the belt.

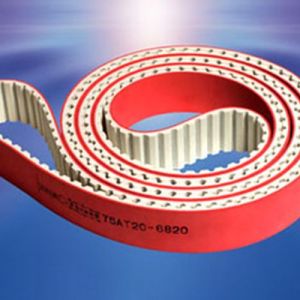

Conveyor drive pulleys are often supplied with diamond grooved lagging as indicated in the adjacent sketch.

‘Diamond grooved lagging’ refers to the pattern in the lagging and this pattern, like with vehicle tyres, enhances the grip or friction even if the belt surface is dirty.

Looking for "Diamond Pulley Lagging Rubber Sheet" ?

Explore More Products